CycloneCC™

Modular Technology

Meet the next generation of carbon capture

CycloneCC™ is a breakthrough cost-effective, space-saving solution. Our ‘Lego-block’, ‘plug and play’ modular design enables small-to-midsize industrial emitters to stagger their carbon capture investment. The technology to catalyse the deployment at these sites is now ready and process intensification and standardisation are key.

At the heart of this innovative technology are Rotating Packed Beds (RPBs), which use centrifugal force to increase the efficiency of the carbon capture process.

A pioneering solution that puts us at the leading edge of innovation in carbon capture and builds on 15 years of engineering excellence in the sector.

Compact and

cost-effective

Process intensification enables the mass transfer equipment to be ten times smaller, reducing the overall unit footprint by up to 50% compared to conventional carbon capture systems.

The result? You save up to 50% on the total installed cost, with no loss in performance.

Minimal disruption

Using modular designs and prefabricated skids reduces your site infrastructure requirements. This makes it easier to integrate our solutions with your existing industrial operations to minimise disruption, maximise cost effectiveness, and simplify plant maintenance.

Easy to scale

CycloneCC™ is 100% pre-fabricated and delivered in modular units that can be added over time to scale in line with your decarbonisation strategy. Units are optimised for industrial emissions and can capture between 75 – 855 tonnes per day (TPD) of CO2 per train.

Standardised designs

With off-the-shelf base designs and ready-made engineering that is customisable for site conditions, we can offer you replicable cost and delivery efficiencies.

Reduced total cost

of ownership

scalable designs

unit footprint

size reduction

Experts in global delivery

- Installed on site in under a week

- System validation has confirmed scale up

- Standardised road truckable design

- Customisable to your site requirements

A rotating revolution

CycloneCC™ intensifies the traditional solvent capture process by combining two proven process intensification technologies.

Each RPB contains a disk of packing material which rotates around its axis. The centrifugal force generated through this rotational motion is significantly greater than the gravitational force seen in conventional packed columns, making RPBs far more effective in mass transfer operations.

Our other technologies

Further resources

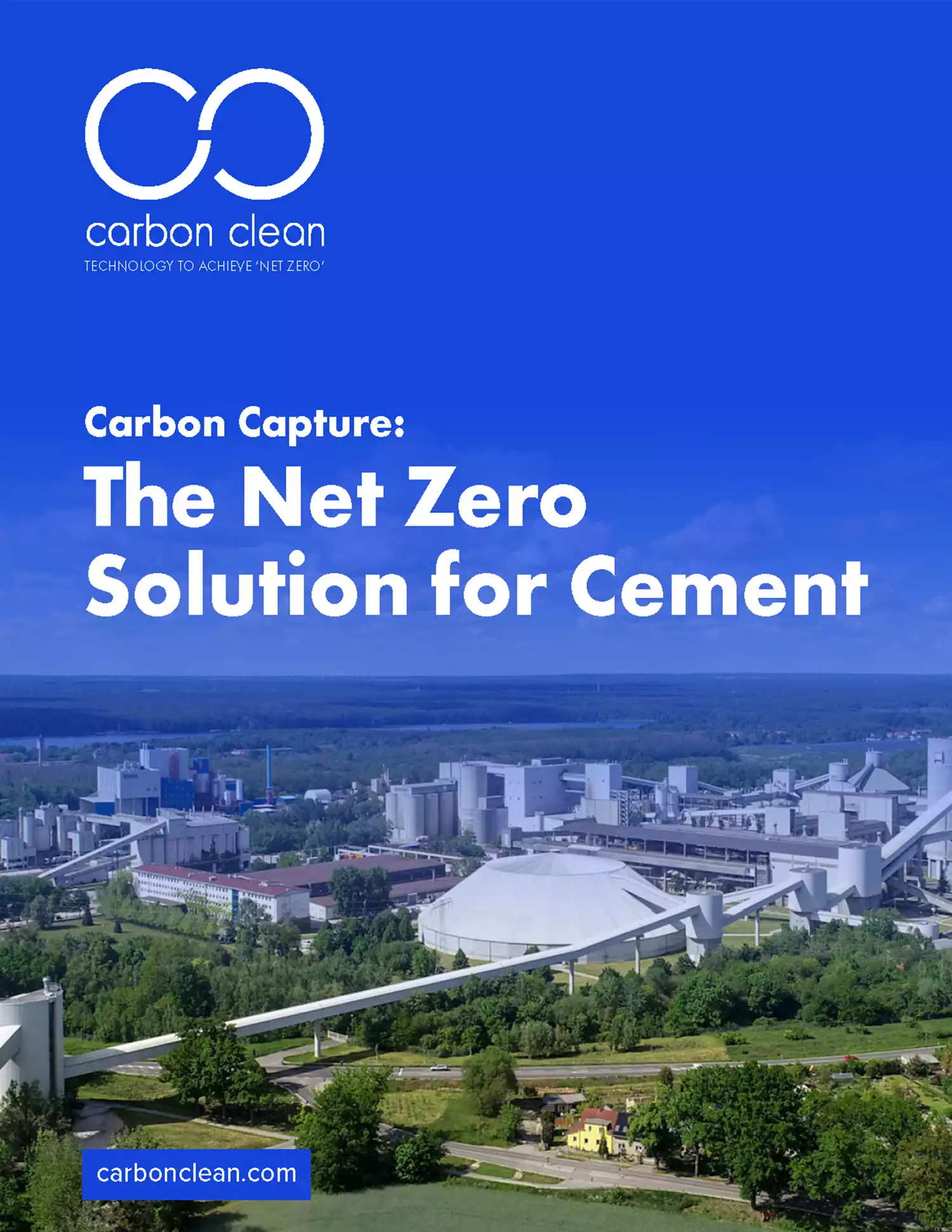

Carbon Capture: The Net Zero Solution for the Cement Industry

The cement industry is uniquely poised to pave the way toward a net zero future. Learn how carbon capture can help

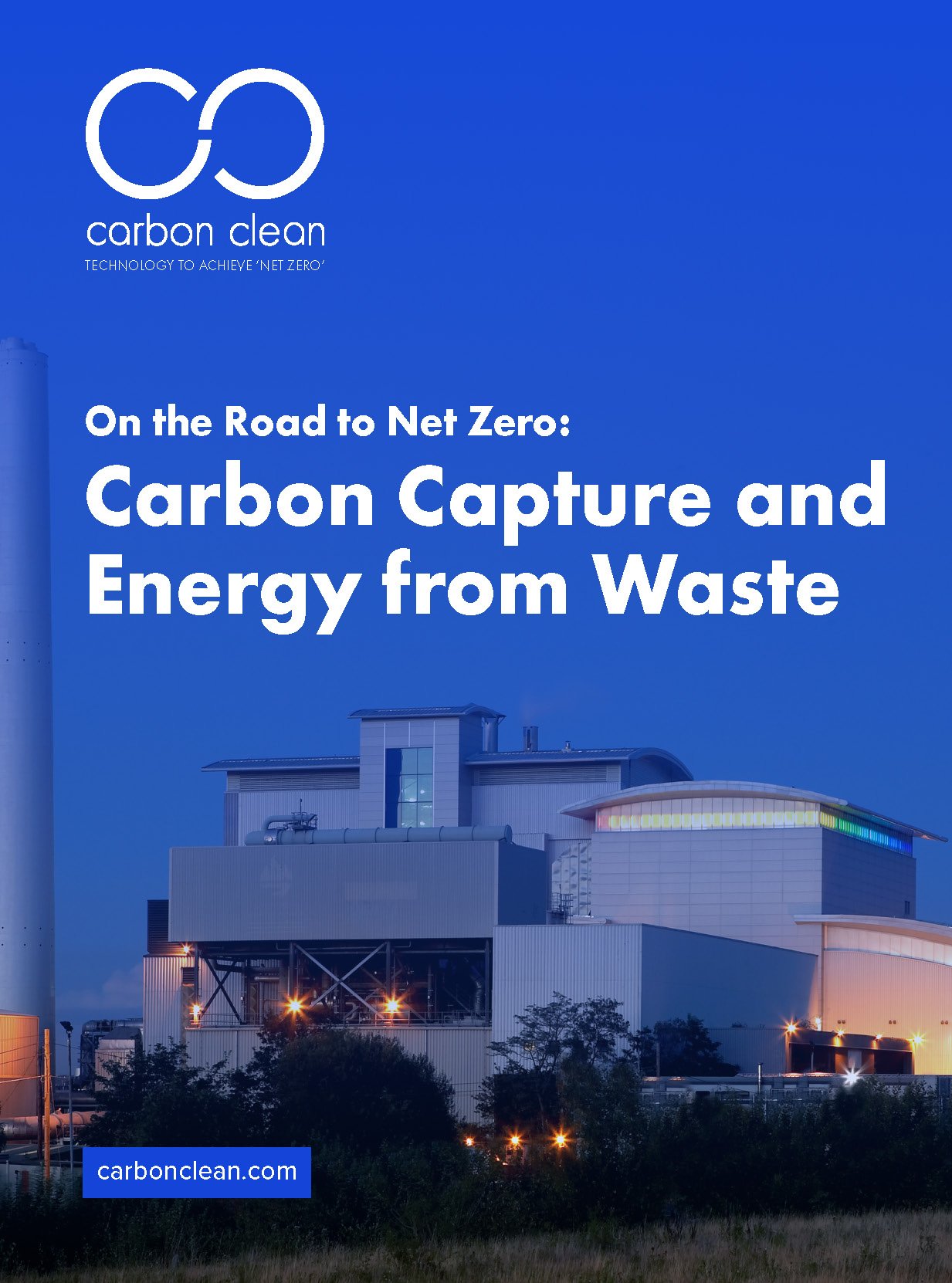

Revolutionising the Energy from Waste Sector with Carbon Capture

When it comes to achieving net zero, energy security, and a circular economy, the Energy from Waste (EfW) sector is a cornerstone industry of the future.

Hydrocarbon Processing Market Survey

Learn about valuable market insights including how experts from sectors such as refining, petrochemical, gas processing, LNG, and engineering view CCUS.

![CC-DIAGRAM-TRIM_4[72]](https://7845802.fs1.hubspotusercontent-na1.net/hubfs/7845802/CC-DIAGRAM-TRIM_4%5B72%5D.gif)