Refineries are under pressure: there is a critical need for the sector to reduce emissions and pave the way toward net zero. However, refineries face unique challenges that other industries don't have to address. How can the industry capitalise on carbon capture for refineries?

In our latest video, Glen Bailey, Director of North America Sales for Carbon Clean, discusses the advantages of solvent-based carbon capture for refineries — and how Carbon Clean's technology directly addresses the industry's unique needs.

What are the core challenges for refineries when considering carbon capture?

Refineries are unique when it comes to carbon capture, with challenges not seen in other industries.

Refineries can be large sprawling industrial complexes, with multiple point sources of flue gas. Each source could have a different composition and sometimes there is a possibility of contaminants. Each source may require a distinct process design.

Finally, the site layout can be very space-constrained, so the typical footprint of carbon capture systems can be a difficult challenge.

Can solvent-based carbon capture help meet those challenges?

Absolutely. Solvent-based carbon capture can be deployed to separate carbon dioxide from a wide range of flue gases at atmospheric pressure. This means that it’s perfectly suited to treat flue gases from either downstream processes or from heat and power generation units at a refinery.

Solvents are specially formulated to extract carbon dioxide from a mixture of other gases. They have been used for decades, and are the most proven and mature carbon capture technologies on the market. Conventional solvents for carbon capture are amine-based, with the most common being MEA.

How does using solvent-based carbon capture technology help the refining industry reach the goal of net zero emissions?

Solvent-based carbon capture will be a key element towards achieving emission-reduction goals. Solvent-based carbon capture can be used to capture 90% or more of CO2 emissions from distributed point sources within a refinery.

How can Carbon Clean’s APBS-CDRMax® solvent benefit a refinery in capturing carbon?

APBS-CDRMax® is an enhanced amine solvent developed by Carbon Clean. This solvent is cost-effective and high-performing, enabling carbon capture systems with reduced Capex. CDRMax™ is more robust and stable compared to traditional solvents, and it reduces the impact of contaminants in the various flue gases being treated.

CDRMax™ also requires much less energy for regeneration versus conventional solvents. It is less corrosive, and Carbon Clean’s solvents have been proven across a range of flue gas compositions.

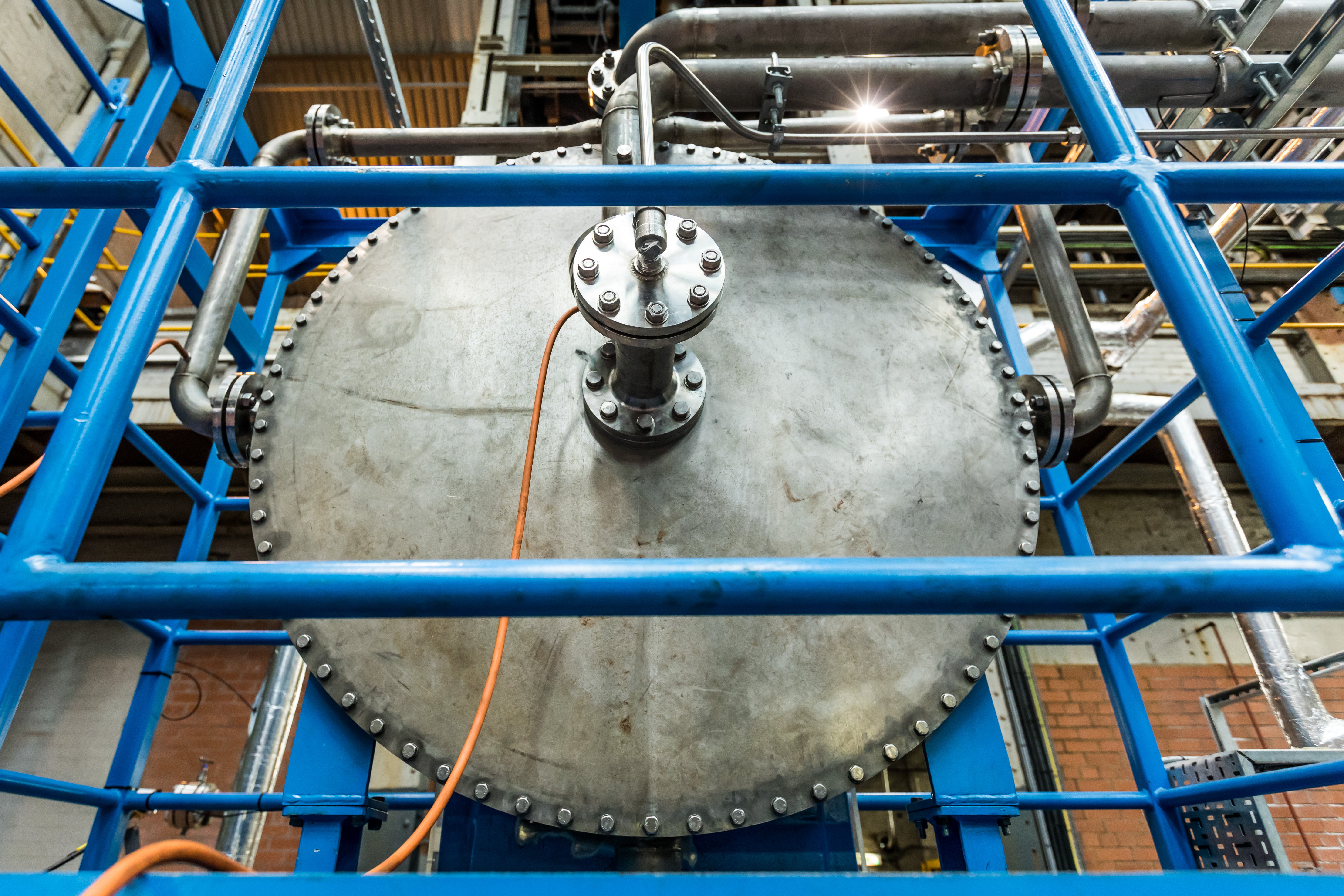

A further benefit for refineries will be Carbon Clean’s CycloneCC technology, currently in development. CycloneCC will replace traditional absorber and stripper columns with a rotating packed bed. Our modular implementations will be well-suited to enable carbon capture in the limited space in refineries.

Has a refinery implemented Carbon Clean’s APBS-CDRMax® solvent technology?

CDRMax™ has been demonstrated at the Technology Centre Mongstad in Norway, capturing carbon dioxide from fluid catalytic cracker off-gas. This is a good example of a challenging point source on a refinery site. CDRMax™ showed excellent performance in this case, demonstrating that this solvent has wide applicability across multiple use cases.

Looking to learn more about the role of solvents in carbon capture — and how they can help refineries achieve net zero? Download our eBook, The Key to Efficient Carbon Capture: High-Performance Solvents, to learn how Carbon Clean's proprietary solvents are making an impact.